Fasteners and Machining: Incorporating Precision and Strength in Manufacturing

Fasteners and Machining: Incorporating Precision and Strength in Manufacturing

Blog Article

Navigating the Globe of Fasteners and Machining: Strategies for Accuracy and Rate

In the complex world of bolts and machining, the quest for precision and speed is a continuous obstacle that requires thorough focus to information and tactical planning. From comprehending the diverse range of fastener types to picking optimum products that can hold up against rigorous demands, each step in the process plays a pivotal duty in attaining the wanted result.

Understanding Fastener Types

When choosing bolts for a project, comprehending the different types readily available is vital for ensuring ideal efficiency and reliability. Bolts are made use of with nuts to hold materials together, while screws are versatile bolts that can be used with or without a nut, depending on the application. Washers are necessary for dispersing the load of the fastener and stopping damages to the material being attached.

Selecting the Right Materials

Comprehending the relevance of picking the right materials is vital in making certain the optimum efficiency and reliability of the chosen fastener types went over formerly. When it involves bolts and machining applications, the product choice plays an essential function in figuring out the general stamina, longevity, deterioration resistance, and compatibility with the intended environment. Various products use differing homes that can dramatically influence the efficiency of the bolts.

Usual products utilized for bolts include steel, stainless steel, brass, light weight aluminum, and titanium, each having its distinct toughness and weaknesses. Steel is renowned for its high toughness and sturdiness, making it ideal for a broad array of applications. Selecting the ideal product includes taking into consideration elements such as stamina requirements, environmental problems, and spending plan constraints to make sure the desired performance and durability of the bolts.

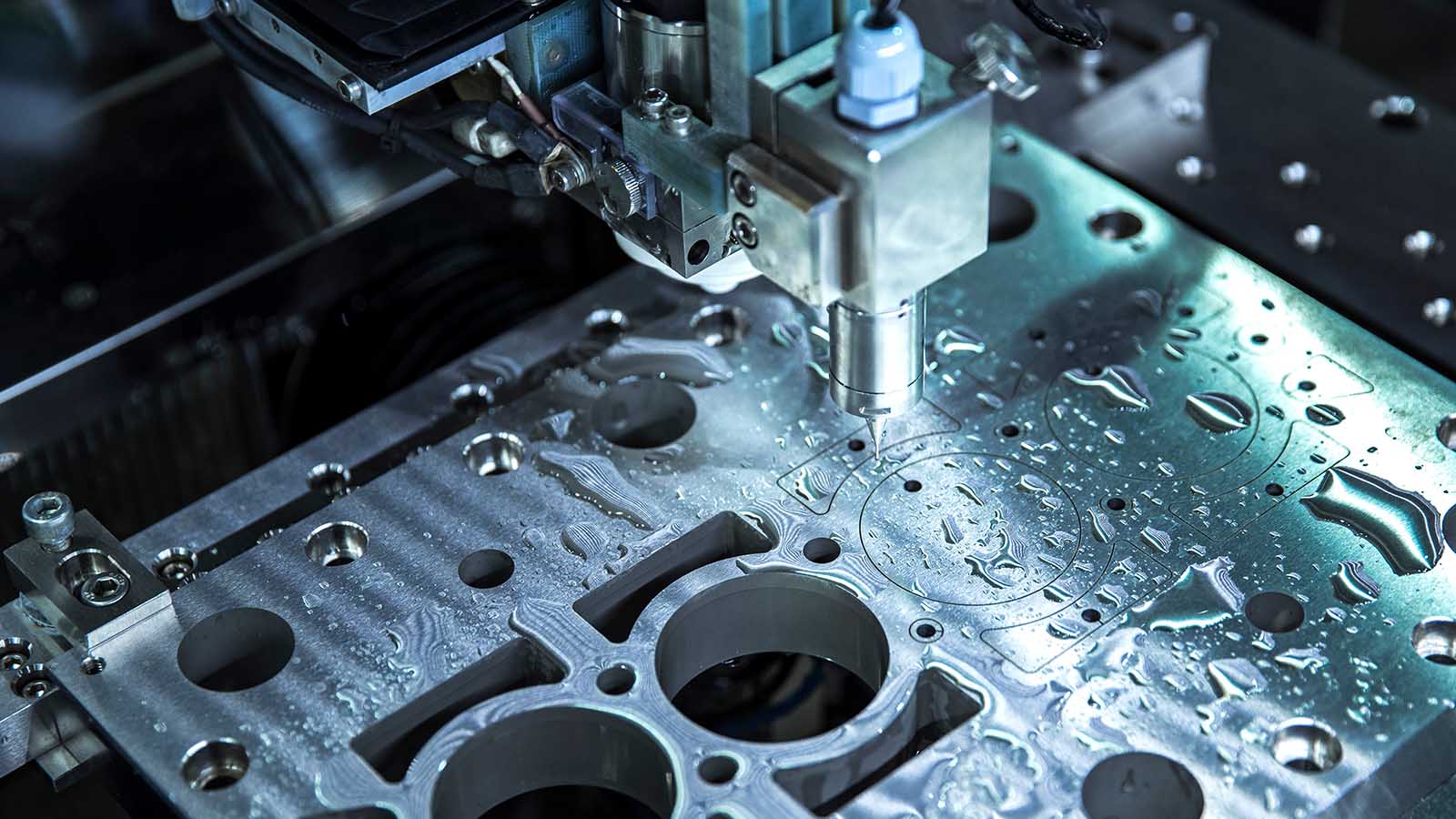

Precision Machining Techniques

In enhancement to CNC machining, other accuracy strategies like grinding, transforming, milling, and drilling play crucial duties in fastener manufacturing. Grinding aids achieve fine surface area coatings and limited dimensional resistances, while turning is commonly used to create cylindrical parts with precise diameters. Milling and boring procedures are necessary for shaping and creating holes in bolts, guaranteeing they fulfill exact specs and feature correctly.

Enhancing Rate and Performance

To maximize fastener manufacturing procedures, it is vital to streamline procedures and implement effective strategies that match accuracy machining techniques. Automated systems can take care of repetitive tasks with precision and speed, permitting employees to focus on even more complicated and value-added tasks. By integrating these strategies, manufacturers can achieve a balance in between speed and precision, eventually boosting their competitive edge in the bolt industry.

High Quality Control Actions

Executing strenuous quality assurance steps is important in guaranteeing the integrity and uniformity of bolt products in the manufacturing process. Quality assurance actions encompass different stages, starting check over here from the choice of resources to the last inspection of the finished fasteners. One essential element of quality assurance is performing detailed material inspections to verify compliance with specs. This includes examining aspects such as product make-up, toughness, and toughness to assure that the fasteners fulfill sector requirements. Additionally, keeping track of the machining processes is vital to maintain dimensional accuracy and surface finish top quality. Making use of innovative technology, such as automatic evaluation systems and precision measuring devices, can improve the accuracy and efficiency of top quality control treatments.

Regular calibration of devices and equipment is necessary to maintain consistency in production and make certain that fasteners satisfy the needed resistances. Executing stringent methods for identifying and attending to non-conformities or problems is crucial in preventing substandard products from going into the marketplace. By developing a comprehensive high quality control framework, makers can maintain the online reputation of their brand and supply fasteners that meet the greatest requirements of efficiency and longevity.

Final Thought

In the elaborate realm of fasteners and machining, the pursuit for precision additional hints and rate is a continuous challenge that requires careful interest to information and critical preparation. When it comes to bolts and machining applications, the product choice plays a vital function in figuring out the general strength, resilience, corrosion resistance, and compatibility with the desired setting. Accuracy machining includes various advanced approaches that make certain the limited tolerances and specifications needed for bolts.In enhancement to CNC machining, various other precision techniques like grinding, transforming, milling, and boring play crucial functions in fastener manufacturing.To enhance fastener manufacturing processes, it is essential to simplify official website procedures and implement efficient strategies that complement precision machining techniques.

Report this page